mod 5

Instructors: Andrea Atkins, Jonathan Enns

Team: Stefan Rankovic

Media: AutoCAD, SketchUp, Lumion, Illustrator & Photoshop

Project Status: Façade System Concept

Awards: Architectural Engineering Best Project (2020)

Spring 2020

Background

In the present time, Modular and Prefabricated Construction has started to become the solution towards the rise in residential demand within the Architecture, Engineering, and Construction (AEC) industry. Both modular and prefab components can significantly lower construction costs and reduce the time it takes to assemble a structure under tight schedules.

The University of Waterloo has asked the class of Architectural Engineering to design a replacement (or additional enclosure) for the Douglas Wright Engineering (DWE) building on campus. The mod 5 project is the definition of a simplistic modular prefabrication system. mod 5 uses a set of five prefabricated wall panels that can adapt and reorganize based on the interior program of the building. Once the wall panels are set into position on each level, a gasket mechanical system is released from all sides of the panels, connecting to the rest of the façade and creating one family. The modular system allows for prompt maintenance in case of panel damage or restructure of interior programming.

Existing Façade on Douglas Wright Engineering Building (DWE)

Investigation

A study of the thermal effectiveness of DWE’s current façade was conducted in order to further understand the purpose of poor energy efficiency for the building. This energy analysis was compared and contrasted with a more modern façade that was designed for the Tatham Centre, also located on campus.

The modern enclosure outperforms the solid masonry wall by about 38%, the major shortcomings being air control barrier failures between openings and wall assemblies, thermal insulation oversights due to improper structural connections and exposed concrete slabs, and under performing glazing units throughout the project. This poor performance will be based around locations where openings are covered with conductive materials, which allow thermal energy to flow out of the building.

The mod 5 project replaces the entire façade enclosure to minimize as much of the existing errors as possible. The original detail drawing illustrates the amount of exposed concrete structure that acts as a thermal release for the building. The thermal lab conducted on the DWE building using THERM, allowed the team to fully understand the common errors made within façade enclosures that can ruin the energy efficiency of the overall building. These lessons were taken into consideration when designing the mod 5 system.

THERM Analysis for DWE

THERM Analysis for Tatham Centre

Engineer.

Attach.

Schedule.

Reorganize.

Detail

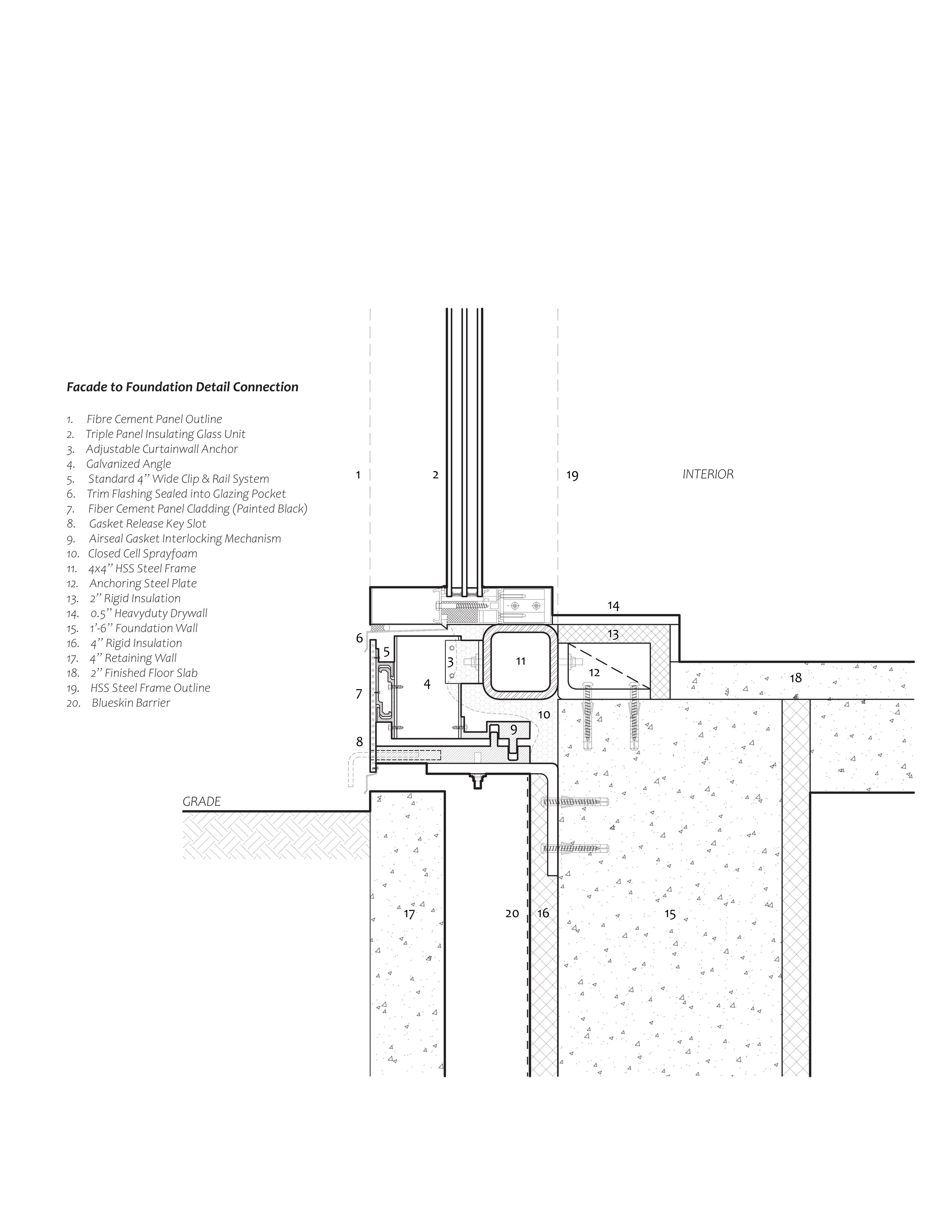

The two L-brackets will ensure the entire wall panel is completely level and set in place prior to the gasket release. The simple connection to the L-brackets allows for a rapid and effortless reorganization based on the interior space. The five different custom panels allow for simplistic choice depending on the amount of privacy needed for the program within the building.

Thermal analysis was done to examine the mod 5 façade system. The R-Values of the composition of materials were implemented into THERM software to get the total R-Values based on sections of the façade.

Assembly

The figures shown illustrate graphically how each modular panel will be assembled to the existing concrete slab structure. Each of the five different wall panel styles has a structural 4x4” HSS skeleton embedded within the prefabricated module. The HSS frame will have two screw extenders that are connected to an L-bracket that is bolted to the existing concrete slab before the panel assembly.

(S.Rankovic)